- Call Us:

+91-9991172496, +91-9640551000

- Email:

sales@amazingstainless.com

Our Services

Our Process

At Amazing Stainless World Pvt Ltd, we follow the below in-house processes:

Automatic Tube GTA welding

At Amazing Stainless World Pvt Ltd, we use hygienic tubing with 2B cold rolling coil to guarantee full penetration and good welding performance, complying with sanitary tubing requirements.

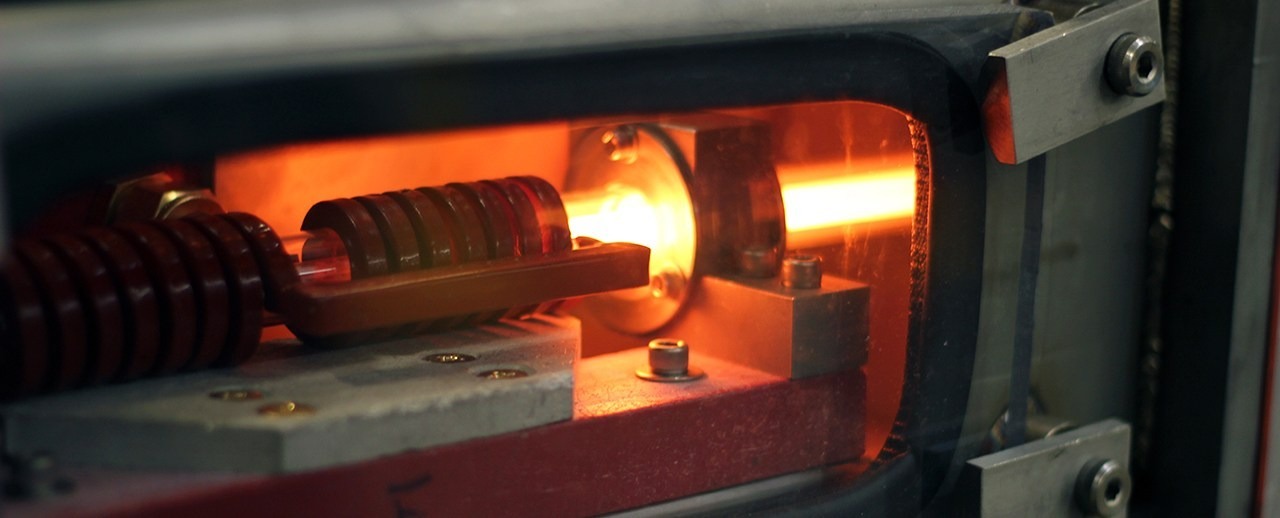

Bright Annealing

Our on-line bright annealing process involves controlled heating between 1040°C-1080°C followed by cooling with quenching water. We utilize 99.999% pure hydrogen for a high-quality surface finish.

Bead Crush

Our bead crush process removes weld bead lines from both the outside and inside, resulting in a smooth surface and achieving better Surface R.A value as per international standards.

Mechanical Polishing Process Inside & Outside

Our mechanical polishing process ensures welding seam integrity with the base metal after heat treatment, resulting in a visible bright surface. Additionally, it creates a uniform and smooth surface that is easy to clean with no scale.

Electro-Polishing

Our electro polishing process involves significant material removal, resulting in an extremely smooth and glossy surface. This process achieves a quality of Ra ≤ 0.38 μm (15 μin).

| Grade | Standard |

|---|---|

| TP304 / 304L / 1.4307 / 316 / 316L / 316Lcs / 1.4404 | ASTM A270 S2 / EN 10217-07 / BS 4825 / ISO / SMS |

| 316Lcs / 1.4404 / 1.4435 | ASTM A270 S2 / ASME-BPE / EN 10217-07 |

| TP304 / 304L / 316L / 904L / 1.4539 and duplex material | ASTM A249 / ASTM A688 / ASTM 269 / ASTM 789 / A790 |

| Grade 1 / Grade 2 | ASTM B 338 |

Product Range

| OD mm | WT mm/inch | Length mm/feet | |||

|---|---|---|---|---|---|

| Min | 12.7 | 0.5 | 0.02" | 6000 | 20 |

| Max. | 101.6 | 4.0 | 0.15" | 12000 | 40 |

Product Finish Specificaon

| Process Designaon | Equivalent to | Surface Treatment | Surface Finish Value (Ra) | ||

|---|---|---|---|---|---|

| Outer Surface | Inner Surface | µ-in | µ-m | ||

| BA - BA | SF0 | Bright Annealed | Bright Annealed | - | - |

| MP - BA | SF3 | Mechanical Polished | Bright Annealed | 30 | 0.76 |

| MP - MP | SF2 | Mechanical Polished | Mechanical Polished | 25 | 0.64 |

| SF1 | 20 | 0.51 | |||

| MP - EP | SF4 | Mechanical Polished | Electro Polished | 15 | 0.38 |

| SF5 | 20 | 0.51 | |||

| SF6 | 25 | 0.64 | |||